Beke 110t3200 CNC Press Brake Hydraulic Sheet Metal Bending Machine for Folding 10feet Steel Plate

Overview Product Description Detailed Photos Certifications Packaging & Shipping Company Profile Customer Photos

Overview

Detailed Photos

CertificationsPackaging & ShippingCompany Profile Customer Photos

Basic Info.

| Model NO. | WE67K 110T3200 |

| Suitable for | Copper, Aluminum, Alloy, Carbon Steel, Stainless Steel |

| Type | Press Brake |

| Throat Depth | 400mm |

| Slide Stroke | 200mm |

| Weight | 8000kg |

| Main Motor Power | 7.5kw |

| Max Bending Thickness for 3m Sheet | 4mm |

| Max Opening Height | 480mm |

| Model | We67K 110t3200 |

| Max Bending Width | 3200mm |

| Transport Package | Cover with Plastic Film |

| Specification | 3850x1850x2600 |

| Trademark | BEKE |

| Origin | China |

| HS Code | 8462299000 |

| Production Capacity | 50 Set/Month |

Product Description

Product Description

| BEKE WE67K Series CNC press brake |

| BEKE WE67K Series CNC press brake is with price that you can afford and long life quality. It has higher bending precision than NC press brake, faster bending speed and easier operation, less failure rate. It can save your time and energy. |

| DELEM DA66T CNC Control system |

| Features: 3D visualisation in simulation and production 17″ high resolution colour TFT Full Windows application suite Delem Modusys compatibility (module scalability and adaptivity) USB, peripheral interfacing User specific application support within the controllers multitasking environment Sensor bending & correction interface |

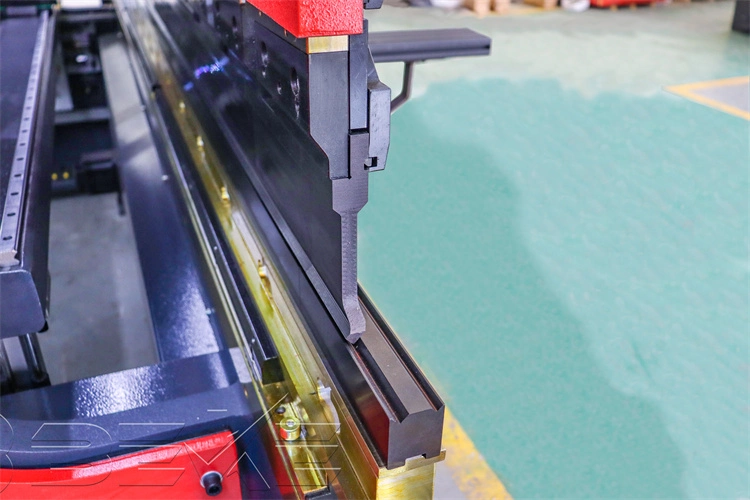

| Punch and Die |

| Material: 42CrMo Overall quenching process, high hardness and good wear resistance.(the tool photos are only for reference, we can also do customization) Can also be designed according to customer product |

| Quick Clamp |

| For fast tool changing |

| Mechanical compensation |

| CNC controlled through system When working, the upward compensation workbench produces an upward force that is equivalent to the force of the main oil cylinder to the workbench, and generates an upward convex curve to compensate for the deformation of the worktable and the slider during work. |

| Backgauge |

| With X, R axes Servo motors for controlling position with high precision Backgauge fingers on double guide rails Taiwan brand ball screw and linear guide rail |

| Hydraulic System |

A closed-loop control hydraulic system is formed by proportional electro-hydraulic valves, grating scales, and synchronouly controlled cylinders on both sides. Each of them is independently limited by the CNC system and they feedback accurate data to ensure the accurate running precision of the slider. SIEMENS main motor SUNNY oil pump Bosch-Rexroth hydraulic valve They are well-known brands with reliable quality, compact structure and beautiful appearance Convenient and quick maintenance |

Send to us