Light Duty High Speed 7 Axis CNC Swiss Automatic Lathe Machine for High

Basic Info.

| Model NO. | JSL-20AB |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Semi-Closed Loop Control |

| Numerical Control | CNC |

| Processing Precision | 0.005-0.01(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | ISO 9001 |

| Condition | New |

| Spindle Motor Power(Kw) | 2.2/3.7 |

| Number of Axis | 7 |

| Spindle Bore(mm) | 22 |

| Max. Spindle Speed(r.p.m) | 8000 |

| Weight (Kg) | 2400 |

| Voltage | 220V/50Hz |

| Dimension(L*W*H)(mm) | 2365 × 1070 × 1800 |

| Positioning Accuracy(mm) | ±0.008 |

| Max. Length of Workpiece(mm) | 200 |

| Max. Turned Length(mm) | 200 |

| Number of Spindles | 2 Spindle |

| Width of Guide Rail(mm) | 20 |

| Machining Capacity | Light Duty |

| Number of Tools | 21 |

| CNC Control System | Fanuc Mitsubishi |

| Transport Package | Standard Marine Wooden Pallet Packaging |

| Specification | Customized Available |

| Trademark | JINN FA |

| Origin | Taiwan China |

| Production Capacity | 200 Set/Sets Per Year |

Packaging & Delivery

Package Size 350.00cm * 230.00cm * 270.00cm Package Gross Weight 4000.000kgProduct Description

Light Duty High Speed 7 Axis CNC Swiss Automatic Lathe Machine for High-Precision Processing (JSL-20AB)Price is different accroding the configurations .7 Axis Swiss CNC Lathe Machine (JSL-20AB):

CNC Lathe Turning Machine Features:- Dual spindle, total 5 axes/6 axes- Adopt Swiss technology,most parts adopt JAPAN/TAIWAN brand- Adopt meehanite resin sand cast iron, after aging treatment, small distortion, good heat stability and high rigidity- Adopt high precision built-in electro-spindle,NSK/NTN super high precise angle contact ball bearing, achieve spindle's high rigidity and good precision retention,spindle flop≤2μm - Adopt TAIWAN HIWIN brand high precision ball screw and linear guideway- Adopt gang type tool, can achieve turning/milling/drilling etc combined machining by side-mounted live tool and C axes- After mount automatic bar feeder, can realize automatic machining- Suitable for complex, small-sized,precise,slender axles workpiece machining

Product Parameters

Here are two types parameters of different CNC system.| Content | FANUC Parameter | Mitsubishi Parameter | ||

| Basic Specifications | Maximum machining diameter of positive spindle | 20mm | 20mm | |

| Maximum machining diameter of auxiliary main shaft | 20mm | 20mm | ||

| Maximum bore diameter of positive main shaft | 10mm | 10mm | ||

| Maximum bore diameter of auxiliary main shaft | 8mm | 8mm | ||

| Maximum tapping of positive main shaft | M8 | M8 | ||

| Maximum tapping of auxiliary main shaft | M6 | M6 | ||

| Maximum bore diameter of side drill | 10mm | 10mm | ||

| Maximum tapping of side drill | M8 | M8 | ||

| Maximum machining length | Standard: 200mm | Standard: 200mm | ||

| Use rotating guide sleeve: 85mm | Use rotating guide sleeve: 85mm | |||

| Tool type: 45mm | Tool type: 45mm | |||

| Number of tools | Outside diameter knife | 8 | 8 | |

| Inner hole cutter | 5 | 5 | ||

| Sidetrack cutter | 4(7) | 4(7) | ||

| End drill | 4 | 4 | ||

| Tool size | 12mm * 12mm *90mm | 12mm x 12mm x 90mm | ||

| Rapid feed | 24 M/min | 24 M/min | ||

| Number of control axes | 7 | 7 | ||

| positioning accuracy | 0.01/100 | 0.01/100 | ||

| Repetitive positioning accuracy | 0.003/200 | 0.003/200 | ||

| Mechanical appearance (length * width * height) | 2365x1070x1800 | 2365x1075x1800 | ||

| Total weight of machinery (Kg) | 2400kg | 2400kg | ||

| Spindle | Motor model and manufacturer | α B80L/8000i | JINN FA Servo motor | |

| Transmission mode | Hidden type | Hidden type | ||

| Motor power | 1.1/3.7KW | 1.1/3.7KW | ||

| Speed range | 15~8000rpm | 15~8000rpm | ||

| Maximum torque | 23.6NM | 23.6NM | ||

| Main shaft through hole diameter/push tube through hole diameter | ψ 29/ ψ 22 | ψ 29/ ψ 22 | ||

| Spindle collet | Jinshang collet type 20 | Jinshang collet type 20 | ||

| Spindle positioning | 5° | 5° | ||

| Model of front bearing of main shaft | 7910 | 7910 | ||

| Spindle bearing accuracy | P4 | P4 | ||

| Diameter of front bearing of main shaft | ψ 50 | ψ50 | ||

| Lubricating medium | NBU15 KLUBER | NBU15 KLUBER | ||

| Spindle cooling mode | Forced air cooling | Forced air cooling | ||

Detailed Photos

Finished Products Display

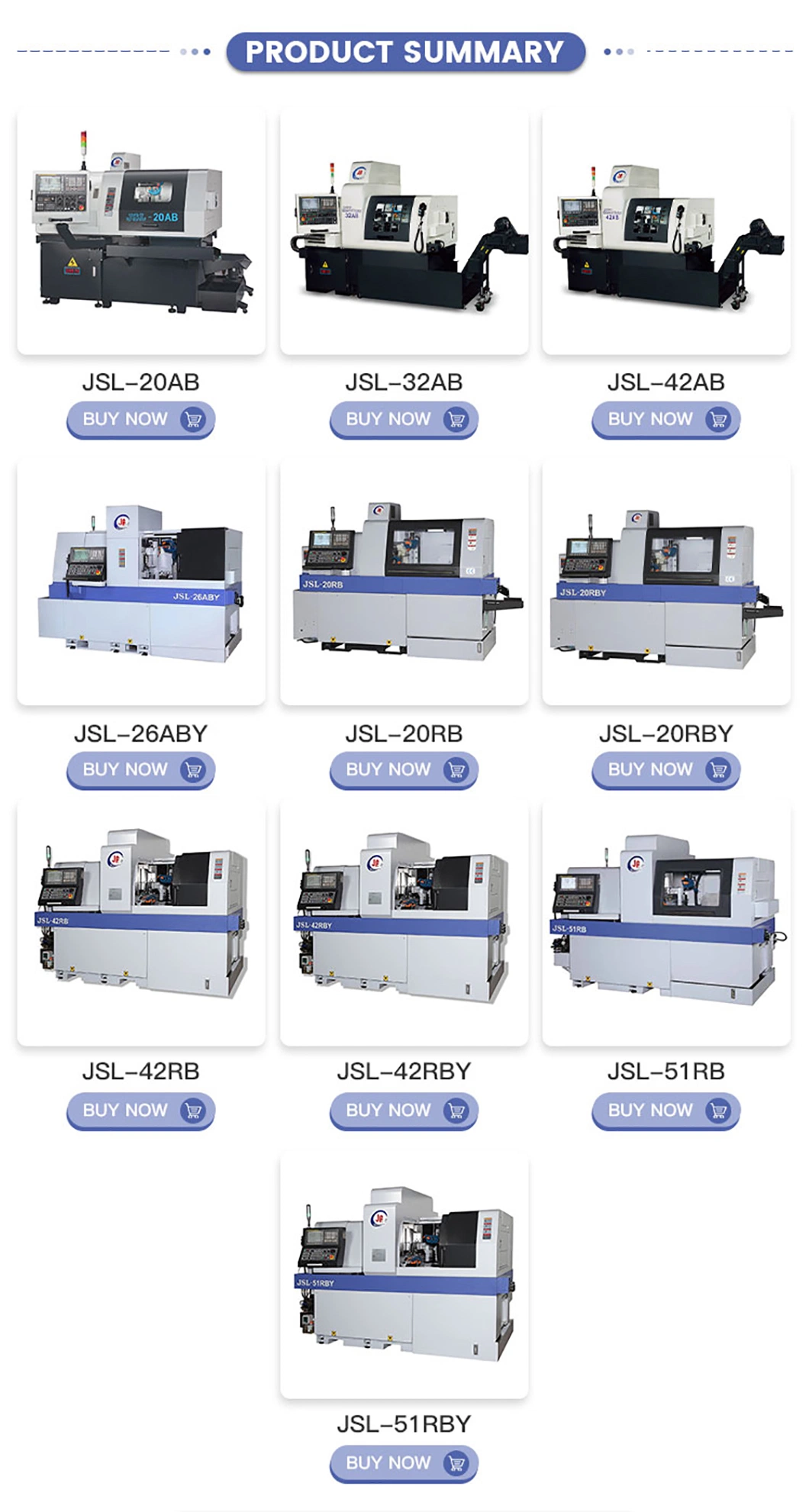

Product Recommendation

Company Profile

Xiongyi intelligent machinery (Changzhou) Co., Ltd. is a limited liability company with independent legal personality approved by the Administration for Industry and commerce. The company is composed of high-precision CNC professional and technical personnel and senior people in the machine tool industry. It is familiar with the market of machine tool industry at home and abroad and has many partners in the industry.The company mainly sells the operation and technical services of Taiwan, China (JINN FA) brand equipment and domestic advanced CNC machine tools, machine tool accessories and precision tools.In line with the company philosophy of "integrity-based, unity of knowledge and practice, win-win future" and the purpose of "customer first, quality first", we make full use of our technical connotation and extensive external information resources, We should exploit the essence of machine tool brands, provide users with high quality CNC equipment that meet user's requirements and product processing needs, and do everything we can to help users improve productivity, competitiveness and increase profits. The company strives to become a friend of every customer and partner, and is willing to go hand in hand with you to create a better future.

Certifications

Packaging & Shipping

FAQ

1.What is your minimum order quantity and warranty?MOQ is one set, and warranty is one year.2.What CNC system do you use?FANUC, SIEMENS, MISTSUBISHI, GSK,SYNTEC. It depends on your choice.3:How can I choose the most suitable machines?

A: Please tell me your specifications ,we can choose the best model for you, or you can choose the exact model. You can also send us the products drawing ,we will choose the most suitable ma-chines for you.4: What's your main products of your company?

A: We specialize in selling all kinds of machine tools, such as CNC lathes, CNC milling machines, vertical machining centers, lathes, Swiss-type lathes, grinding machines and special fixtures for machine tools, tools, nonstandard fixtures, tools5: Where is our factory located? How can I visit there?A :Our company is located at C307, Block C, Boyunhui, No. 18, Xingao Road,Niutang Town, Wujin District, Changzhou City, Jiangsu Province, China. You are warmly welcomed to visit us.6. What is your trade terms?

A: FOB, CFR and CIF all acceptable.7: What's the Payment Terms?

A: T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight.