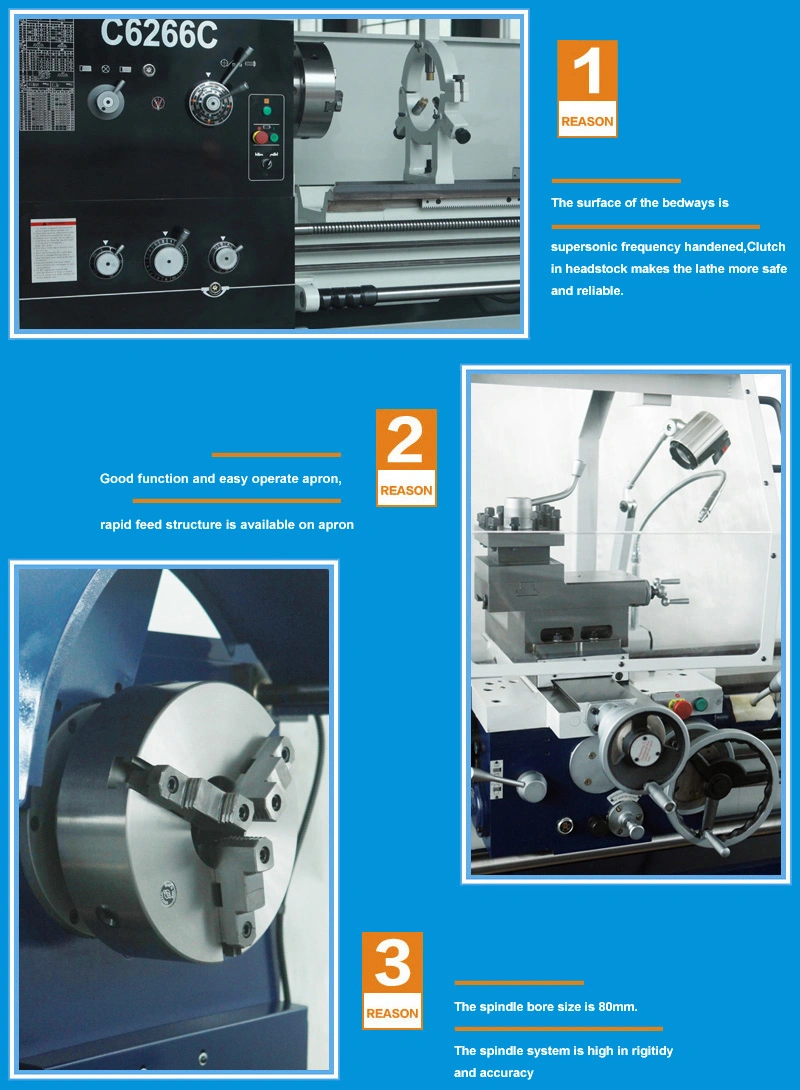

Heavy Duty Universal Horizontal Gap Bed Lathe Machine (C6266C)

LATHE FEATURES: High precision gap bed lathe machine swing over bed 660mm 1. The surface of the bedways is supersonic fr

Basic Info.

| Model NO. | C6266C CQ6280 CS6266C CS6250B CS6250C |

| Automatic Grade | Semiautomatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Width of Bed | 250mm |

| Spindle Bore | 105mm |

| Taper of Spindle Bore | Mt5 |

| Max. Swing Over Cross Slide | 420mm |

| Max.Swing Over Bed | 660mm |

| Transport Package | Plywood Case |

| Specification | Cast Iron |

| Trademark | HOTON |

| Origin | China |

| HS Code | 8458190000 |

| Production Capacity | 10 PCS/Month |

Product Description

LATHE FEATURES:

High precision gap bed lathe machine swing over bed 660mm

1. The surface of the bedways is supersonic frequency.

2. The spindle bore size is 105mm. The spindle system is high in rigitidy and accuracy.

3. There is no need for change gears. The machine can turn about 89 kinds of metric, Inch, Module and D. P. Threads.

4. An automatic stopping device is used to realize automatic stop for the machining of a workpiece of a certain length.

SPECIFICATIONS:

| MODEL | C6266C | ||

| Max. Length swing diameter | Over bed | mm | 660 |

| Over carriage | mm | 420 | |

| In gap | mm | 870 | |

| Max. length of workpiece | mm | 1000/1500/2000/3000 | |

| Effective length in gap | mm | 240(9") | |

| Spindle | Spindle bore | mm | 105(4") |

| Taper of bore | 113mm 1:20 | ||

| No.of speed | 12 | ||

| Range of speeds | r.p.m | 36-1600 | |

| Thread cutting | Metric range /NO | 1 ~14mm/22 | |

| Inch range/no | 28 ~2 t.p.i/25 | ||

| D.p. Rang/no | 56 ~4 D.P/24 | ||

| Module range/no | 0.5~7mm/18 | ||

| Range of feeds | Leadscrew | mm | 0.028-6.43 |

| Cross | mm | 0.012-2.73 | |

| Rapid traverse | Leadscrew | m/min | 4.5 |

| Cross | m/min | 1.9 | |

| Tailstock sleeve | External diameter | mm | 75(2-61/64") |

| Taper of bore | MT5 | ||

| Max. Travel | mm | 150 | |

| Max. travel of compound rest | mm | 145(5-3/4") | |

| Max. cross slide travel | mm | 310(12-3/32") | |

| Max. size of tool shank (WxH) | mm | 25x25(1"x1") | |

| Power of main motor | kw | 7.5(10HP) | |

| Overall dimensions (LxWxH) | mm | 2500/3000/3500/4500x1100x1450 | |

| Net weight | kg | 2500/2700/3000/3350 | |

| STANDARD ACCESSORIES : | SPECIAL ACCESSORIES |

| 325 3-jaw chuck Face plate Morse reduction sleeve 113 1:20/M.T.No.5 Centers M.T.No.5 Wrenches Operation manual | 400 4-jaw chuck 250 Drive plate Steady rest Follow rest Taper turning attachment |

| Contact Us: |

| Andy Wang TENGZHOU HOTON MACHINERY CO.,LTD Tel:0086 632 5633796 MP:0086 13506328892 hotonmachinery.en.made-in-china.com |

| Company Profile: |

| Tengzhou Hoton Machinery Co.,LTD was established in 2006, and is the professional machine manufacturer in China. There are 480 workers, of whom 60 are engineers. It has an area of 46,000 square meter, general assets 30,000,000. It has a store of 350 equipments and the good ability of products design & manufacturing. It has export quality permit from 2007, and has export right given by the State Foreign Economic Trade Committee in 2008. |

| The leading products: "Hoton" series of CNC machines, Lathes, Milling machines, Drilling machines,Grinding machines, Saws, Sheet metal machines, Metal forming machines, and other machine accessories.Some products have national patent.It has fourteen series, over eighty models by itself. It has the ability of making 100,000 sets every year. All the products are designed perfectly and has high quality high performance and low price, and the excellent quality guarantee system. The products have past ISO9001 and CE certification since 2009. The products have been export to five continents, over forty countries and areas. It resulted to the attraction of client abroad and home, the quickly promotion of products sale. |

| Tengzhou Hoton Machinery Co.,Ltd. is willing to make common progress and developments with all the customers. Quality first,Constantly perfecting skills. |

Send to us