Surface Grinding Machine (GS

Features: This series of surface grinder is most suitable for the grinding steel, casting and non-ferrous parts of machi

Basic Info.

| Model NO. | GS-300A, GS-400A, GS-500A, GS-630A |

| Certification | CE, ISO 9001 |

| Condition | New |

| Voltage | as Your Request |

| Grinder | Surface Grinder |

| Warranty Period | One Year After Delivery |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Transport Package | Wooden case/Pallet |

| Specification | ISO9001: 2000, ISO14001: 2004, CE |

| Trademark | TIMAC |

| Origin | China |

| HS Code | 84601900 |

| Production Capacity | 1000sets/year |

Product Description

Features:This series of surface grinder is most suitable for the grinding steel, casting and non-ferrous parts of machine manufacturing industry.

The accuracy of the machine has reached the National Standard for horizontal spindle & rectangular worktable surface grinder.

The longitudinal movement of the worktable is driven by vane pump, which makes the movement smooth and low noise.

The bearings of the wheel head spindle adopt bimetal shell bearing, which can afford heavy impact and make the machine able to carry out heavy load grinding.

The cross movement of the wheel head can be driven by hand or by hydraulic oil automatically. It is easy to operate. The vertical feed of the wheel head is driven by hand. It is also assembled with rapid elevating motor, which can reduce the intention of work labor as well as enhance the work efficiency.

The machine moves smoothly and has reliable performance, low noise and stable accuracy. It is easy to operate and deeply welcomed by the customers.

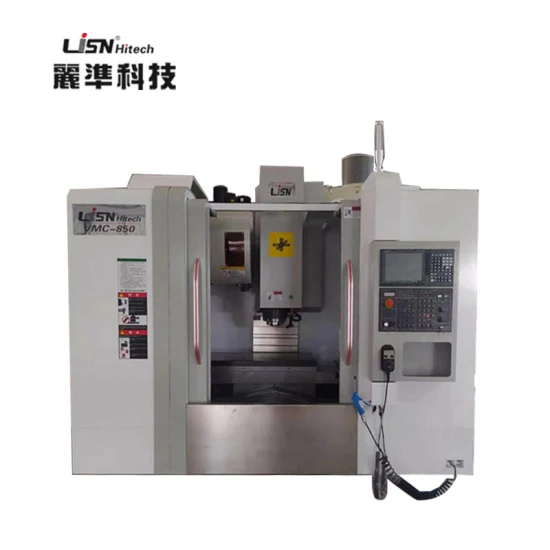

Real Photos:

| Model | Unit | GS-300A GS-300B GS-300C | GS-320A GS-320B GS-320C | GS-400A GS-400B GS-400C | GS-500A GS-500B GS-500C | GS-630A GS-630B GS-630C | GS-700A | GS-800A | |

| Worktable size | Width | mm | 300 | 320 | 400 | 500 | 630 | 700 | 800 |

| Length | mm | 1000/1600/2200/3000/4500 | 1000/1600/2200/3000/4500 | 1000/1600/2200/3000/4500 | 1000/1600/2200/3000/4500 | 1250/1600/2200/3000/4500 | 1250/1600/2000 | 1250/1600/2000 | |

| Max processing dimension | Width | mm | 300 | 320 | 400 | 500 | 630 | 700 | 800 |

| Length | mm | 1000/1600/2200/3000/4500 | 1000/1600/2200/3000/4500 | 1000/1600/2200/3000/4500 | 1000/1600/2200/3000/4500 | 1250/1600/2200/3000/4500 | 1250/1600/2000 | 1250/1600/2000 | |

| Height | mm | 400 800 1200 | 400 800 1200 | 400 800 1200 | 500 800 1200 | 500 800 1200 | 600 | 600 | |

| Max. distance between spindle center line and worktable surface | mm | 575 975 1375 | 575 975 1375 | 700 1000 1400 | 700 1000 1400 | 700 1000 1400 | 825 | 825 | |

| Longitudinal moving speed of worktable | m/min | 3-27 | 3-27 | 3-25 | 3-27 | 3-27 | 6-25 | 3-25 | |

| T-slot number/width | pcs*mm | 3*18 | 3*18 | 3*18 | 3*22 | 3*22 | 3*22 | 3*28 | |

| Wheelhead cross moving | Consecutive feed speed | m/min | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-4.5 | 0.5-2.5 | 0.5-2.5 |

| Intermittent feed speed | mm/t | 3-30 | 3-30 | 3-30 | 3-30 | 3-30 | 3-20 | 3-20 | |

| Hand wheel feed | mm/gra | 0.02 | 0.01 | 0.01 | 0.175 | 0.175 | |||

| Wheelhead vertical moving | Rapid feed | mm/min | 400 | 400 | 400 | 400 | 400 | 600 | 600 |

| Hand wheel feed | mm/gra | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | 0.005 | |

Send to us