Br

Basic Info.

| Model NO. | BR-570 |

| Tool Holder | Single-tool Holder CNC Lathe |

| Power Source | Mechanical Drive |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Table |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Bar Capacity | 52mm |

| Highest Spindle Speed | 4200rpm |

| Z Axis Limit Travel | 810mm |

| The X-Axis Limit Stroke Limit | 270mm |

| Maximum Processing Length | 750mm |

| Spindle Bore | 66mm |

| Max.Swing Over Cross Slide | 400mm |

| Max.Swing Over Bed | 570mm |

| Transport Package | Free Fumigation Plywood Packaging Steel Base |

| Specification | 2100*1836*1435mm |

| Trademark | BORUI |

| Origin | Shandong China |

| HS Code | 8458110090 |

| Production Capacity | 500 Pieces/Year |

Packaging & Delivery

Package Size 2500.00cm * 1500.00cm * 1550.00cm Package Gross Weight 3000.000kgProduct Description

BR-570 China Slant Bed CNC Lathe Machine for Sale

Product Description

The machine is the machine is suitable to process all kinds of small and middle-size shaft and plate work piece,and could also turn various threada,circle arc,circular cone,inside and outside surface of revolved body.this machine is widely used in sanitary,valve,electrical appliance,instrument,automobile,motorcycle,bearings and so on.CNC Lathe Features

1. Highter accuracy Taiwan linear guideways2. Highter speed spindle unit,optional homemade spindle3. Highter rigidity cast iron4. Integrated automatic lubrication5. One-piece casting slat bed cnc lathe

Product Parameters

| Machine Model | Model | BR570-520 | BR570-750 |

| Major parameter | The maximum turning diameter on the bed | Φ570 | Φ570 |

| maximum machining diameter | Φ500 | Φ500 | |

| Maximum machining diameter on the tool holder | Φ230 | Φ230 | |

| Maximum processing length | 520(8″) | 750(8″) | |

| Spindle and chuck parameters | Spindle head form (optional chuck) | A2-6(8″) | A2-6(8″) |

| Recommended spindle motor power | 11-15KW | 11-15KW | |

| Spindle speed | 4200rpm | 4200rpm | |

| Spindle hole diameter | Φ66 | Φ66 | |

| Bar diameter | Φ52 | Φ52 | |

| Feed section parameters | X/Z axis screw specifications | 3210/4010 | 3210/4010 |

| X-axis limit travel | 270 | 270 | |

| Recommended X-axis motor torque | 11N.M | 11N.M | |

| X/Z axis rail specifications | 45/45 | 45/45 | |

| Z axis limit travel | 610 | 810 | |

| Recommended Z-axis motor torque | 11 N.M | 11 N.M | |

| X, Z axis connection mode | Direct | Direct | |

| Turret or Gang | Optional turret (special configuration) | CLT-100-12T | CLT-100-12T |

| Recommended turret center height dimension | 100mm | 100mm | |

| Tailstock | Socket diameter | 80 | 80 |

| Socket travel | 80 | 80 | |

| Tailstock maximum stroke | 480 | 480 | |

| Tailstock sleeve tapered hole | MT5# | MT5# | |

| Overall Dimension | Bed type and inclination | Integrated/30° | Integrated/30° |

| Machine size(L * W * H) | 1800×1320×1438 | 2100×1386×1435 | |

| Weight | Weight (approx. weight) | 2500kg | 2700kg |

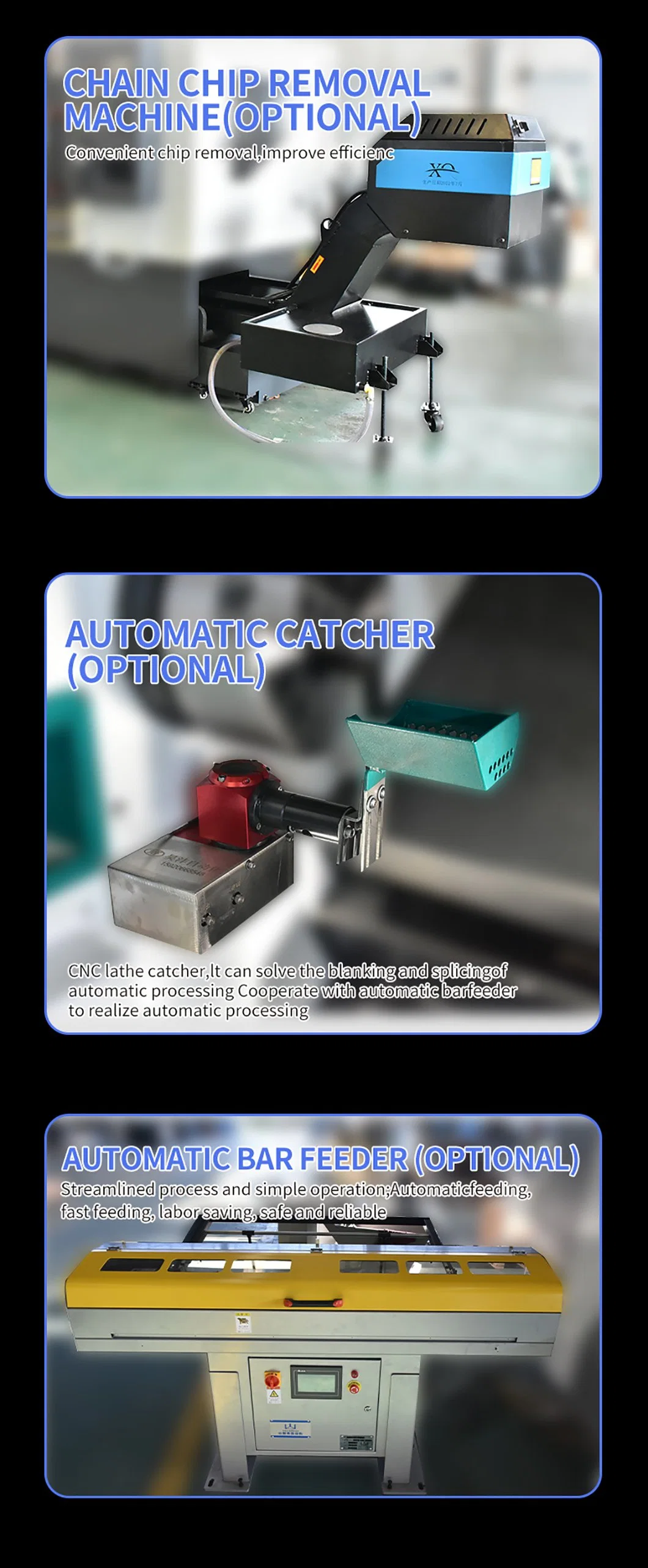

Optional Accessories:

1. NC System: KND1000Ti, Fanuc Oi Mate-T2. Main Motor: Servo 11/15 KW 3. Turret: 8 station electric turre 4. Chuck: 8″Non-through hole hydraulic chuck 5. 8″Non-through hole hydraulic chuck (Taiwan)6. 8″through hole hydraulic chuck(Taiwan)7.10″Non-through hole hydraulic chuck8. 10″through hole hydraulic chuck(Taiwan)

9.Chip conveyor 10.Steady Rest

11.Without tailstock

12.Inverter 11 KW

Details Display

Packaging & Shipping

Packing shippingFor machine: usually by sea; For documents: by international express, eg. DHL,TNT or EMS.For packing :Free fumigation plywood packaging steel baseour service1. Technical support online service provided.2. Technical files service provided.3. Machine operation video provided4. On-site training service provided.5.Spare parts replacement and repair service provided.6 All of the questions will be replied within 8 hours7. If you need to develop products with your own specification, we can help you to work it out.8. Always be honest, never lie to customer, and never declare anything we don't have

Company Profile

Since 1996,20 years' history for machine tool manufacturing10 years' history for exportTotal 2 manufacturing bases in chinaSino-germany technology cooperationProduction of 8 categories, more than 130 kinds of productsSet up design&research center at TAIWAN Exported to total 48 countries in the world covered most areasOne-stop shopping for nearly all other types' machine tools

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model You can also send us the products drawing ,we will choose the most suitable machines for you . 2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as CNC Lathe Machine ,CNC Milling Machine ,Vertical Machining Center ,Lathe Machines ,Drilling Machine ,Radial Drilling Machine ,Sawing Machine ,Shaper machine and so on . 3: Where is our factory located? How can I visit there?A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us. 4. What is your trade terms?A : FOB, CFR and CIF all acceptable. 5: What's the Payment Terms ?A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight . 6: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set ) We want to know:1.What's your Industrial Voltage? 2.We strongly suggest you to tell us size, material of your workpiece for our evaluation, if possible, better to send us workpiece drawing, so that we can recommend you most suitable model! 3.If need CIF Price, please kindly tell us the port of destination.