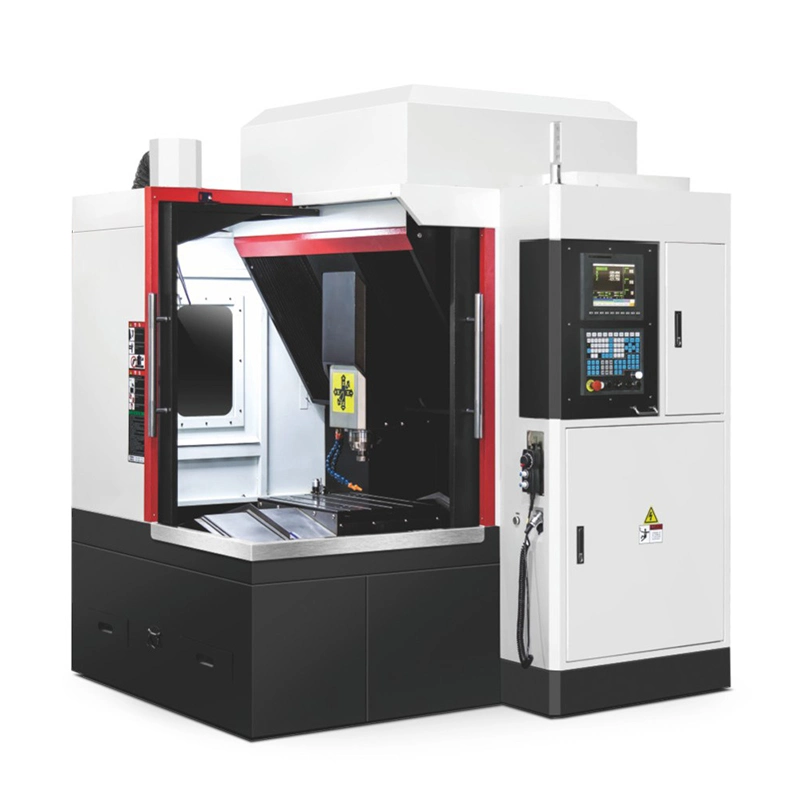

CNC Machine Tools CNC Engraving Milling Machine Center for Metal Embossing Mold Making

Basic Info.

| Model NO. | T1080 |

| Process Usage | Metal-Cutting CNC Machine Tools |

| Movement Method | Contour Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Certification | CE |

| Condition | New |

| Repeat Precision | +-0.003mm |

| Power | 5.5kw 380V 3 Phase |

| Precision | +-0.005/300mm |

| Working Table | 800*1000 |

| Applicable Industries | Machinery Repair Shops, Manufacturing Plant, Mold |

| Type | 3 Axis CNC Machine |

| Max Working Speed | 6m/ Min |

| Spindle Speed | 24000 Rpm |

| Name | Cutting Mold CNC Milling Machine |

| Max Load | 400kg |

| Tool Alignment | Auto Tool Checking |

| X/Y/Z Speed | 24/24/124 M/Min |

| Spindle Motor | 7.5kw |

| System | Syntec/Mitsubishi/Fanuc/Siemens |

| Spindle Taper | Bt30 |

| Transport Package | Sea Worthy Plywood Case |

| Specification | 3400*2100*2600 |

| Trademark | WT |

| Origin | Dongguan City China Prc |

| HS Code | 8459310000 |

| Production Capacity | 2000PCS/Year |

Packaging & Delivery

Package Size 2750.00cm * 2150.00cm * 2673.00cm Package Gross Weight 5300.000kgProduct Description

CNC Machine Tools CNC Engraving Milling Machine Center for Metal Embossing Mold Making

Product Description

CNC Engraving And Milling Machine For Steel Metal Cutting Embossing Mold Is A Tool Machine Center Which can be engraved or milled. On the basis of the engraving machine, the power of the main shaft and the servo motor is increased, the bearing capacity of the bed is increased, and the high speed of the main shaft is maintained, and more importantly, the precision is high. The engraving and milling machine is also developing towards high speed, which is generally called high-speed machine. It has stronger cutting ability and very high machining accuracy. It can also directly process materials with a hardness above HRC60 and form it at one time. It is widly used in Metal Copper Aluminum Precision Milling And Engraving.

Product Paramenters

| Item | Unit | T-540 | T-650 | T-760 | T-870 | T-1080 |

| X-axis travel | mm | 400 | 600 | 600 | 800 | 1000 |

| Y-axis travel | mm | 500 | 600 | 700 | 700 | 800 |

| Z-axis travel | mm | 200 | 260 | 280 | 350 | 500 |

| Spindle nose to table | mm | 50-220 | 50-310 | 30-290 | 70-470 | 70-470 |

| Three-axis guide width | X/Y:30 Z:25 | X/Y:30 Z:25 | X/Y/Z:30 | X/Y/Z:MSA35 | X/Y/Z:MSA35 | |

| Table size | mm | 500*400 | 600*600 | 600*700 | 800*800 | 800*1000 |

| T-slot | mm | 6*16*90 | 6*16*90 | 6*16*90 | 7*18*100 | 9*18*100 |

| Max load capability | kg | 250 | 300 | 300 | 400 | 400 |

| Standard spindle | Motorized spindle | Motorized spindle | Motorized spindle | Motorized spindle | Motorized spindle | |

| Spindle speed | rpm | 3000-24000 | 3000-24000 | 3000-24000 | 3000-24000 | 3000-24000 |

| Spindle power | kw | 3 | 3 | 3 | 5.5 | 5.5 |

| Spindle taper | ER25/BT30 | ER25/BT30 | ER25/BT30 | ER25/BT30 | ER25/BT30 | |

| Maximum cutting feed rate(X/Y/Z) | mm/min | 8000 | 8000 | 8000 | 8000 | 8000 |

| Rapid speed(X/Y/Z) | m/min | X/Y/Z:15 | X/Y/Z:15 | X/Y/Z:15 | X/Y/Z:24 | X/Y/ Z:24 |

| Ball screw diameter/pitch | mm | X/Y/Z:32/5 | X/Y/Z:32/5 | X/Y/Z:32/5 | X/Y:40/6 Z:32/5 | X/Y:40/6 Z:32/5 |

| Positioning accuracy | mm | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 | ±0.005/300 |

| Repeatability | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 | ±0.003 |

| Air pressure | kgf/cm² | 6 | 6 | 6 | 6 | 6 |

| Net weight of machine | kg | 3200 | 3400 | 3600 | 4800 | 5300 |

| Area | mm² | 1950*1895 | 1950*1895 | 1950*1895 | 2450*2150 | 2750*2150 |

| Machine height | mm | 2355 | 2355 | 2355 | 2673 | 2673 |

| System | Syntec 21MA/E80 | |||||