Heavy Duty Lathe Metal Lathe Horizontal Lathe Machine Ca6180 Brake Lathes Universal Turning Machine

Package Size 370.00cm * 114.00cm * 175.00cm Package Gross Weight 2980.000kg Heavy Duty Lathe Metal Lathe Horizontal Lath

Basic Info.

| Model NO. | CA6180 CA6280 |

| Tool Holder | 4-Way Tool Station |

| Power Source | Joint Drive |

| Controlling Mode | Artificial |

| Automatic Grade | Semiautomatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001, SGS |

| Condition | New |

| Width of Bed | 400mm |

| Max. Length of Work Piece | 750/1000/1500/2000/2200/3000/4000mm |

| Spindle Speeds | 10-1400rpm/16-1400rpm |

| Hole Through Spindle | 52/82/105mm |

| Section of Turning Tool | 25X25mm |

| Max. Swing in Gap | 1020mm |

| Effective Gap Length | 210mm |

| Max. Swing Over Carriage | 540mm |

| Max.Swing Over Bed | 800mm |

| Transport Package | Plywood Cases |

| Specification | 3700*1140*1750mm |

| Trademark | Schuler |

| Origin | Shandong China |

| HS Code | 8458190000 |

| Production Capacity | 180 Piece/Year |

Packaging & Delivery

Package Size 370.00cm * 114.00cm * 175.00cm Package Gross Weight 2980.000kgProduct Description

Heavy Duty Lathe Metal Lathe Horizontal Lathe Machine Ca6180 Brake Lathes Universal Turning MachineProduct Picture:

Product Features:

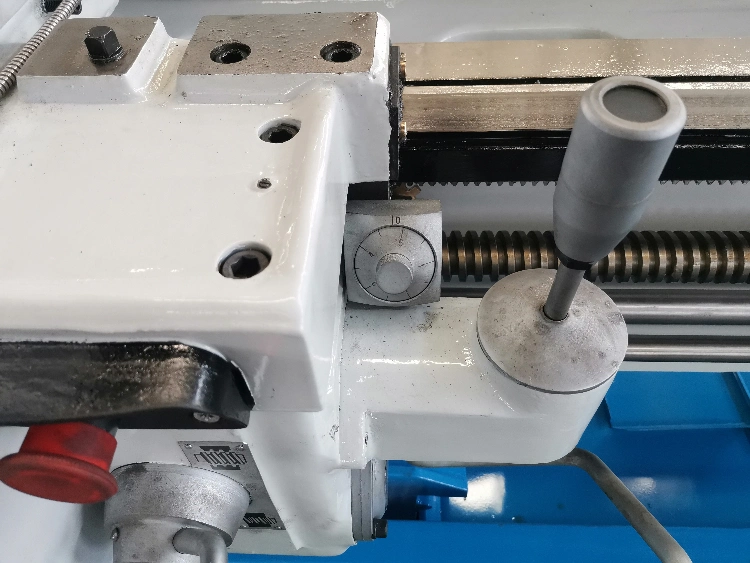

1. Machine headstock and bed. Tail seat. Manually scrape the tray between the joints. The machine has been rigorously tested to ensure the accuracy and stability of the machine.2. The machine tool uses high-strength cast iron and adds special materials such as copper and chrome. The bed rail width is 400mm and the bed rail quenching depth is 4mm, which effectively improves the wear resistance and stability of the machine tool.3, head bed box lubrication using cycloidal pump for cyclic forced lubrication. It protects the headboard from the clean and heat-dissipating properties of the hot southern weather, effectively extending the life of bearings and gears.4. The machine tool spindle adopts Wafangdian bearing, the spindle through hole is φ52mm, and the machine tool gear adopts precision grinding, which effectively improves the gear hardness and reduces the machine noise.5. The machine tool adopts domestic brand screws, and the silk mother adopts high-quality bronze alloy to ensure wear resistance and precise maintenance.6. The machine tool adopts four-station high-strength tool holder. The tool holder size is 25x25mm.

Standard accessories:

1.3-jaw chuck2.Center¢re sleeve3.Wrenches4.Oil gun5.Operation manual

Optional accessories:1.Steady rest2.Follower rest3.4-jaw chuck4.Face plate5.Thread chasing dial6.Longitudinal automatic trip7.Live center 8.Quick change toolpost9.Taper copy ruler10.4-position longitudinal trip

Lathe Machine Technical Parameters:

| Specifications | CA6180/CA6280 |

| Max.Swing over bed | 800mm |

| Max.Swing over carriage | 540mm |

| Max.Swing in gap | 1020mm |

| Effective gap length | 210mm |

| Max.Length of work piece | 750mm-40000mm |

| Width of bed | 400mm |

| Section of turning tool | 25×25mm |

| Spindle speeds | 10-1400rpm/16-1400rpm(24 steps) |

| Hole through spindle | 52mm,(80mm),[105mm] |

| Spindle taper | Mohs6(MT6)(Ф90 1∶20)[Ф113 1∶20] |

| Number of feeds | 64Species(kinds)(for each) |

| Range of metric threads(kinds) | (1-192mm)44Species(44 kinds) |

| Range of inch threads(kinds) | (2-24tpi)21Species(21 kinds) |

| Range of module threads(kinds) | 0.25-48(Modulus39Species)(Module 39 kinds) |

| Range of pitch threads(kinds) | 1-96DP(37Species)(37kinds) |

| Max.Tail stock spindle travel | 150mm |

| Tail stock spindle diameter | 75mm |

| Taper of tail stock spindle center hole | Mohs5(MT5) |

| Main motor | 7.5KW(10HP) |

| Overall dimensions for750mm | 2550×1140×1750mm |

| Overall dimensions for1000mm | 2700×1140×1750mm |

| Overall dimensions for1500mm | 3200×1140×1750mm |

| Overall dimensions for2000mm | 3700×1140×1750mm |

| Overall dimensions for2200mm | 4030×1140×1750mm |

| Overall dimensions for3000mm | 4850×1140×1750mm |

| Overall dimensions for4000mm | 5800×1140×1750mm |

| Weight for 750mm | 2520kg |

| Weight for 1000mm | 2720kg |

| Weight for 1500mm | 2980kg |

| Weight for 2000mm | 3260kg |

| Weight for 2200mm | 3490kg |

| Weight for 3000mm | 420kg |

| Weight for 4000mm | 4850kg |

As a professional manufacturer of lathe machines, we want our customers to know of our commitment to providing the latest products to all customers.

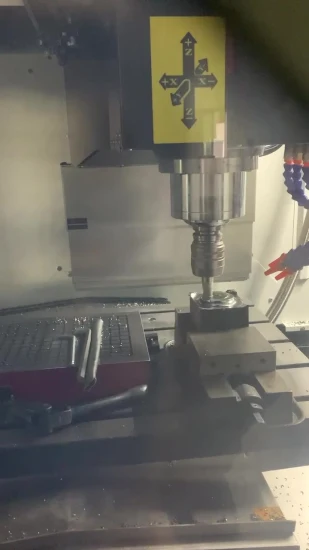

Lathe Macine Details Picture:

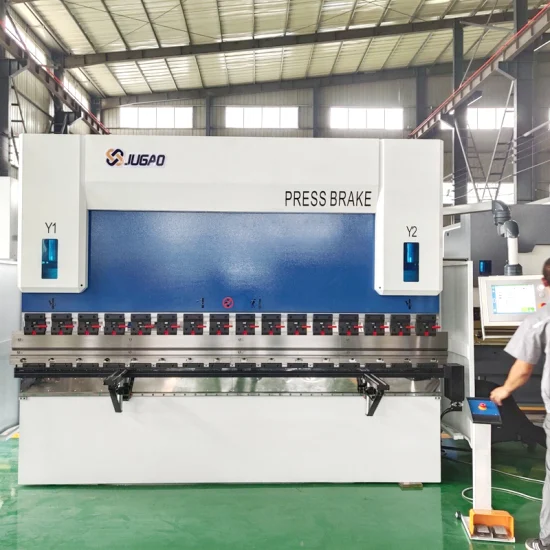

Lathe Machine In the Workshop:

Lathe Machine Package delivery:

The Package of Metal Lathe CA6150 CA6250 Gap Bed Lathe Machine for sale is export standard plywood case with iron plate below ,very strong and durable .The Metal Lathe CA6150 CA6250 Gap Bed Lathe Machine for sale will be shipped to customers by land freight or sea freight .

Our Company:FAQ1. What level of service do you provide ?--->Your inquiry will be replied within 24 hours.2. Technology support by providing operation?training videos?---->Professional after-sales service team. Give reasonable offers with the best quality.3. What is our advantages?----> Competitive price: We can meet your budget and best-selling business very well. OEM Accepted: We can produce customized design. Good Service: We treat clients as friends and provide problem solving anytime you need. Good Quality: We have strict quality control system. Good reputation in the market. Fast & Delivery: We have big discount from forwarder (Long-term Contract).4. Can you customize the machine for the customer?---->Yes. We can, if you need customized services, please contact us5. What is the MOQ?---->We usually provide 1 set for customers to test.6.What is your delivery time?---->The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

7.What is your payment method?---->We prefer to do 100% T/T (30% T/T in advance, 70% T/T before shipment)

8.Agents Wanted:

---->We have strong partnerships in Europe, America, South America, India, Southeast Asia and South Africa. We also supply OEM service, and we are looking for agents in these areas. In the further, we want to develop SCHULER to a global brand. Wherever you are from, we are looking forward to explore new market with you.

If any questions pls feel free to contact me

Contact information :Shandong Schuler CNC Machinery Co,Ltd.Add: Tengzhou City ,Shandong Province ,ChinaEdwin

Send to us