XL8145 High Precision Conventional Vertical Horizontal Universal Drilling Milling Machine

Basic Info.

| Model NO. | XL8145 |

| Milling Cutter Structure | Various |

| Controlling Mode | Artificial |

| Automatic Grade | Manual |

| Precision | High Precision |

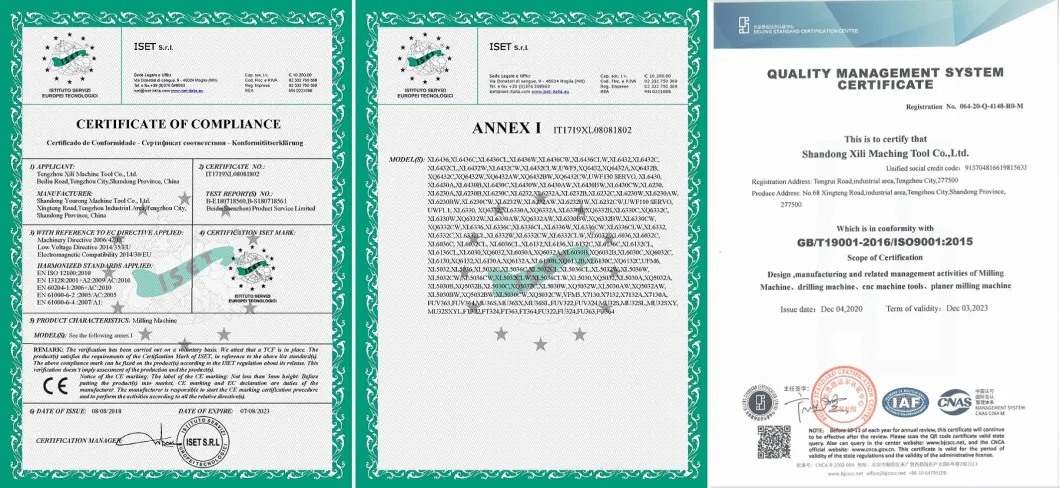

| Certification | GS, CE, RoHS, ISO 9001, ISO |

| Condition | New |

| Table Travel(X/Y/Z) | 600/450/450mm |

| Max Load | 300kg |

| Table Size | 850X450mm |

| Spindle Speed | Stepless,40-260 & 260-2000rpm |

| Feed Torque(X/Y/Z) | 10/10/15nm |

| Manual Feed(X/Y/Z) | Electrical Handwheel |

| Power Rapid Feed(X/Y/Z) | 1200mm/Min |

| Power Feed Speed(X/Y/Z) | 10-1000mm/Min |

| Lead Screw(X/Y/Z) | Ball Screw |

| Horizontal Spindle | ISO40 |

| Spindle Motor | 5.5kw |

| Lubrication | Automatic Centralized System |

| Spindle Stroke | 60mm |

| Vertical Spindle | ISO40 |

| Vertical Head | 45 Degree Swivel (L&R) |

| Transport Package | Plywood Case on Steel Pallet |

| Specification | voltage, color customized |

| Trademark | XILI / OEM |

| Origin | China |

| HS Code | 8459590000 |

| Production Capacity | 60sets/Month |

Product Description

XL8145 High Precision Conventional Vertical Horizontal Universal Drilling Milling Machine

Product Description

Δ Spindle:√ step-less spindle speed, in high & low speed ranges, suitable for high-speed-fine-machining & low-speed-powerful-machining

√ vertical & horizontal spindles combined, for flexible operation

√ 60mm spindle stroke, milling and drilling functions are available

Δ Working feed:

√ X/Y/Z-axis ball screws, good precision√ X/Y/Z-axis driven by 3 independent servo motors, can realize X/Y/Z-axis synchronous feeding√ servo motors for spindle and feeding, machine with low noise, good precision, easy to maintenance√ X/Y/Z-axis with electronic handwheels, for easy and precise manual-feeding√ vertical & horizontal combined work-tables, for flexible clamping of workpiece√ fitted with automatic centralized lubrication system, for automatic timing lubrication

Product Parameters

| Items | XL8132 | XL8140 | XL8145 |

| Working area | |||

| Worktable size (L×W) | 750x320mm | 800x400mm | 850x450mm |

| T slot (Width x No. x pitch) | 14x5x63mm | 14x6x63mm | 14x7x63mm |

| Vertical table size | 890x225mm | 1020x225mm | 1190x250mm |

| T slot (Width x No. x pitch) Vertical table | 14x3x63mm | ||

| Max. load of table | 160kg | 200kg | 300kg |

| Torque of feed motor (X) | 7.7Nm | 7.7Nm | 10Nm |

| Torque of feed motor (Y) | 7.7Nm | 7.7Nm | 10Nm |

| Torque of feed motor (Z) | 10Nm | 10Nm | 15Nm |

| Spindle axis-to-table surface distance(Horizontal) | 145-545mm | 145-545mm | 170-620mm |

| Spindle nose-to-table surface distance(Vertical) | 50-450mm | 50-450mm | 75-525mm |

| Travels | |||

| Longitudinal travel (X) | 405mm | 500mm | 600mm |

| Transverse travel (Y) | 305mm | 400mm | 450mm |

| Vertical travel (Z) | 400mm | 400mm | 450mm |

| Feeds of X Y Z axis | 10-1000mm/min | ||

| Rapid feed | 1200mm/min | ||

| Spindle | |||

| Spindle speed (V&H) | 2 steps; 40-260rpm, 260-2000rpm | ||

| Spindle taper (V&H) | NT40 | ||

| Vertical quill travel | 60mm | ||

| Main motor power | 3.7kW | 3.7kW | 5.5kW |

| Others | |||

| Machine size (L×W×H) | 1500x1700x1800mm | 1500x1700x1800mm | 1600x1800x2000mm |

| Net weight | 1450 kg | 1550 kg | 1750 kg |

Standard Configuration

| No. | Item | Specification |

| 1 | automatic centralized lubrication system | - |

| 2 | water cooling system with spray nozzle | - |

| 3 | CE Schnider electrical components | - |

| 4 | LED work lamp | - |

| 5 | supporting frame for horizontal milling | - |

| 6 | draw bar | - |

| 7 | horizontal milling arbor | Ø16, Ø22, Ø27, Ø32 |

| 8 | reducer sleeve | MT1, MT2, MT3 |

| 9 | milling chuck set | 2, 3, 4, 5, 6, 8, 10, 12mm |

| 10 | tools & metallic tool box | - |

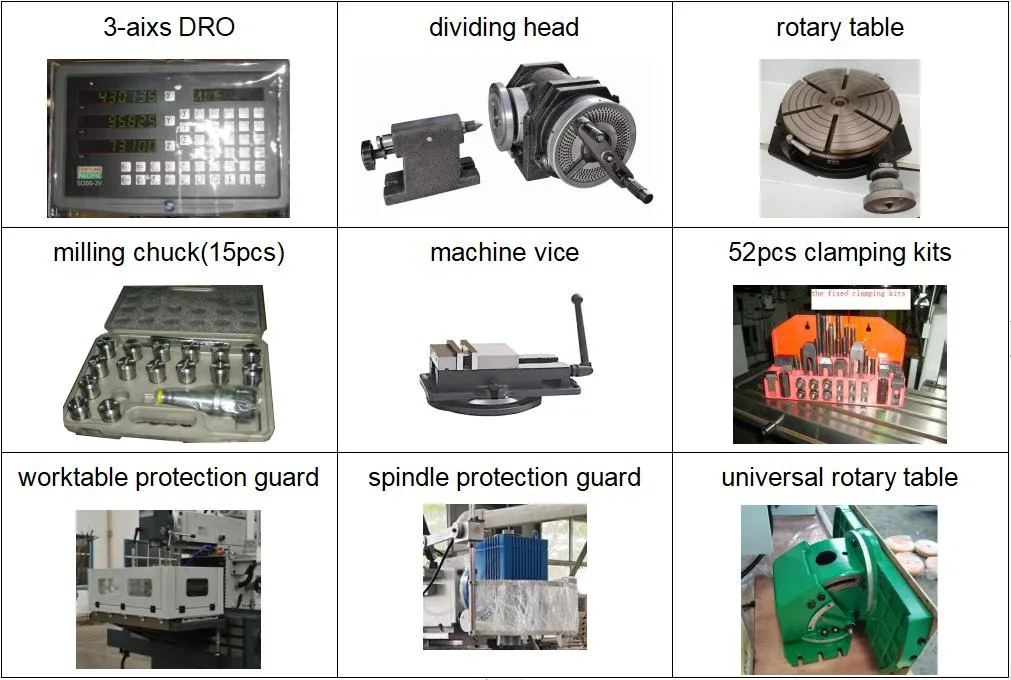

Optional Configuration

Packaging & Shipping

Delivery time: generally 3 months production time after confirmation of orderPacking type: machine is covered with damp-proof plastic film, then packed in plywood case (with steel pallet)Packing size: 2100 x 1900 x 2250mm (L / W / H), can be delivered in 20GP container.

Certifications

Products are strictly according to Europe standard, with CE certificate

Company Hot Products Link

FAQ

1. What is the MOQ ?Minimum order quantity is 1 set.2. What is the payment term ?Usually we prefer T/T. 30% deposit, 70% balance payment against machine ready to delivery photos and videos.Other payment terms are also acceptable after discussion.3. What is the trade terms ?Usually is FOB.Others like CIF, CFR, EXW...... are also acceptable.4. How long is the guarantee ?12 month after machine's delivery from factory.Within warranty, we guarantee spare parts free of charge and online supports for installation, operation, maintance and trouble shooting etc.5. What kinds of machines do you supply?Company specialized in producing CNC & manual milling machines. Include:CNC gantry machining centerVertical machining centerSimple NC milling machineConventional manual milling machines (Vertical, Horizontal, Universal, Turret mill, Swivel head mill, Power sliding ram type, Bed type, Tool milling machine, Gantry type etc.)5. How can I believe your company ?XILI Machine Tool has more than 20 years milling machine production history, covers an area of about 50000 square meters, with 20 million CNY fixed assets and more than 200 employees.Xili Machine Co., Ltd. is a ISO9001 company, all products are with CE certificate.Welcome your inquiry and visiting.