3 Axis 4 Axis 5 Axis CNC Milling Ma Turning Machine Tool Machinery Vertical Machine Vmc850 Machining Center CNC Vertical Machining CNC Machining Center

3 Axis 4 Axis 5 Axis CNC milling ma turning machine tool machinery Vertical Machine Vmc850 Machining Center CNC Vertical

Basic Info.

| Model NO. | VMC850 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001 |

| Condition | New |

| Spindle Speed | 8000rpm |

| Tool Changer | 24PCS |

| Spindle Motor | 7.5kw |

| Re-Positioning | 0.008mm |

| Machine Weight | 4000kg |

| Rapid Speed | 36m/Min |

| Max Feed Speed | 10m/Min |

| Distance Spindle to Table | 150-650mm |

| Table Load | 400kg |

| Spindle Taper | Bt40 |

| Distance Spindle to Column | 550mm |

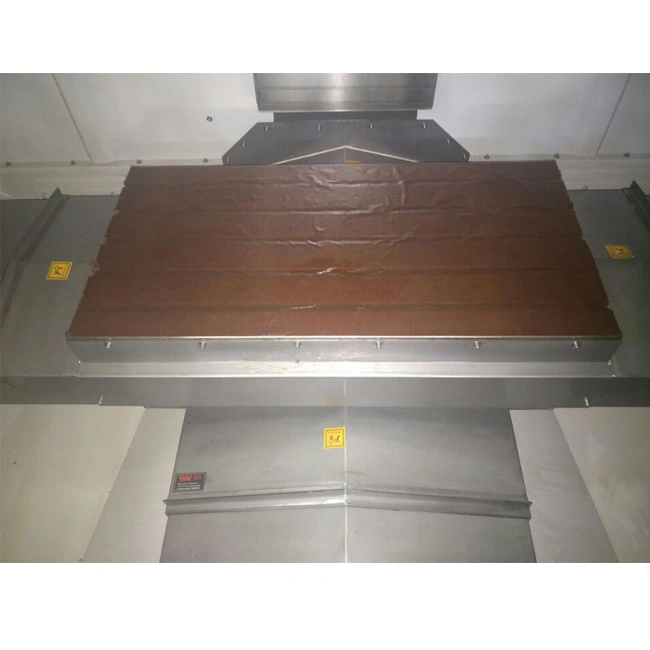

| Table Size | 1000X500mm |

| Table Travel | 800X500X500mm |

| Name | Vertical CNC Machining Center |

| Transport Package | W/Case by Sea |

| Specification | 5T |

| Trademark | NONE |

| Origin | China |

| HS Code | 84571010 |

| Production Capacity | 200/Month |

Product Description

3 Axis 4 Axis 5 Axis CNC milling ma turning machine tool machinery Vertical Machine Vmc850 Machining Center CNC Vertical Machining CNC Machining Center1.Disc type manipulator ATC efficiently improves machine working efficiency.2.XYZ-axis adopts precision roller linear guide-way, which is with big load capacity, realize rapid movement, and ensure position accuracy.3.Ultra-large "" type column design ensure best stability of column and spindle assembly.4.Built- - in type and high rigidityspindle ensure high precision and high efficiency cutting features.5.Wide and solid bed and thickened and lengthened saddle ensure machine with high stability andheavy-duty cutting features.6.XYZ- -axis adopts precision double -nut ball-screwtransmission, and imported special bearing, pre-load assembly, all factor sorganize high rigidity and stable ransmissin system.

| ltem | unit | VMC850 |

| Worktable size | mm | 1000*500 |

| T-slot(N*W*D) | mm | 5-18-90 |

| Max. load bearing of worktable | Kg | 400 |

| X axis travel | mm | 800 |

| Y axis travel | mm | 500 |

| Z axis travel | mm | 500 |

| Distance from column front to Spindle center | mm | 550 |

| Distance from table top surface to Spindle nose | mm | 150-650 |

| Spindle hole taper | BT40 | |

| Spindle power | KW | 7.5 |

| Max. Spindle speed | rpm | 8000 |

| X axis | 2 | |

| Y axis | 2 | |

| Z axis | 2 | |

| X/Y/Z | NM | |

| Max. feed speed | mm/min | 1-10000 |

| Rapid feed speed (XYZ) | mm/min | 36/36/36 |

| Positioning accuracy(XYZ) | mm | 0.02/0.016/0.016 |

| Re-positioning accuracy(XYZ) | mm | 0.008/0.006/0.006 |

| Tool Magazine | ||

| Tool magazine capacity | 24 | |

| Tool chinge time(T-T) | s | 2.5 |

| Machine dimensionL*W*H | mm | |

| Machine weight | Kg | 4000 |

ACCS. OF 4 Axis Vertical Machining Center VMC850 with Fanuc Controller

| Vertical machining center VMC850 | ||

| ITEM | DESCRIPTION | |

| 1 | Model | VMC 850 |

| 2 | Color | BLACK AND WHITE |

| 3 | Voltage | 380 v 50 hz |

| 4 | Spindle | Taiwan spindle BT40/10000RPM (highest speed 10000rpm) |

| 5 | Axis | X,Y axis Taiwan or Germany linear guide ways and Z axis Harden box type |

| 6 | Leadscrew | Taiwan or Germany ball screws |

| 7 | Tool magazin | Taiwan round type tool magazine with 24 tools |

| 8 | Bearing | Germany F AG bearings |

| 9 | Linear guideway | Taiwan linear guideway |

| 10 | Other configuration | spindle blowing chip removal system |

| spindle air curtain protection | ||

| auto centralized lubrication system | ||

| rigid tapping | ||

| two water cooling, one air cooling | ||

| electrical hand wheel, working lamp, RS232 interface, alarm light | ||

| DNC online processing | ||

| CE Electrical | ||

1.Front chip-removal full-closed cover with chip removal device2.Water flow through spindle4.4 axis function5.Oil coolant type spindle6.Direct connected spindle7.Oil and water separator8.Working-piece and tools measuring device 9.Open-door power off function10.High speed and precision function11.Heightened column(bridge type or rising block)

4 Axis Vertical Machining Center VMC850 with Fanuc Controller

CERTIFICATEOur Services:1. Your inquiry and email will be replied within 24hours. 2. If you need to develop products with your own specification, we can help you to work it out.3. Always be honest, never lie to customer, and never declare anything we don't have.4. Customer First:,we offer best Quality and Service!FAQ:1. Payment Method:30% deposit T/T in advance, rest against the copy of B/L or before delivery.2. Delivery Time:one week3. MOQ:1 set machine.If you need machine with your own specification, logo, packing, etc, please negotiate with us.4. Shipping: For machine: Usually by sea;For documents: by international express, eg. DHL,TNT or EMS

Wc67y :next

Send to us